Less damage: prevention really is better than cure

Product damage during transport or storage leads to frustration, costs, and delays, not just for you as the sender, but also for your customer. Damaged products result in returns, additional processing, and lower satisfaction. Moreover, damage often causes the loss of something less visible: time, energy, and raw materials.

At Topa, we believe prevention is better than repair. That’s why “less damage” is one of the key focus areas in our approach to reducing the Total Cost of Packaging (TCP). By aligning packaging closely with your product and logistics process, you can prevent unnecessary costs and waste.

Causes of damage

Damage often occurs when packaging does not properly fit the product or the transport route. Think of insufficient protection against shocks, vibrations, or temperature fluctuations. Incorrect stacking or too much empty space in a box can also lead to damage.

The consequences? Returns, repair or replacement costs, and extra transport movements. It’s not just inconvenient, it costs money and creates more waste and emissions.

How you can reduce damage

We start with an analysis of your logistics process. Where in the chain does damage occur? Which environmental factors play a role? Based on this, we determine the best packaging solution for your situation.

In many cases, we can help with a standard solution from our range. Topa offers a wide selection of proven packaging products that are ready to use and effective in many situations. If something more specific is needed, we’ll develop a custom solution together, tailored to your product, dimensions, and loading conditions.

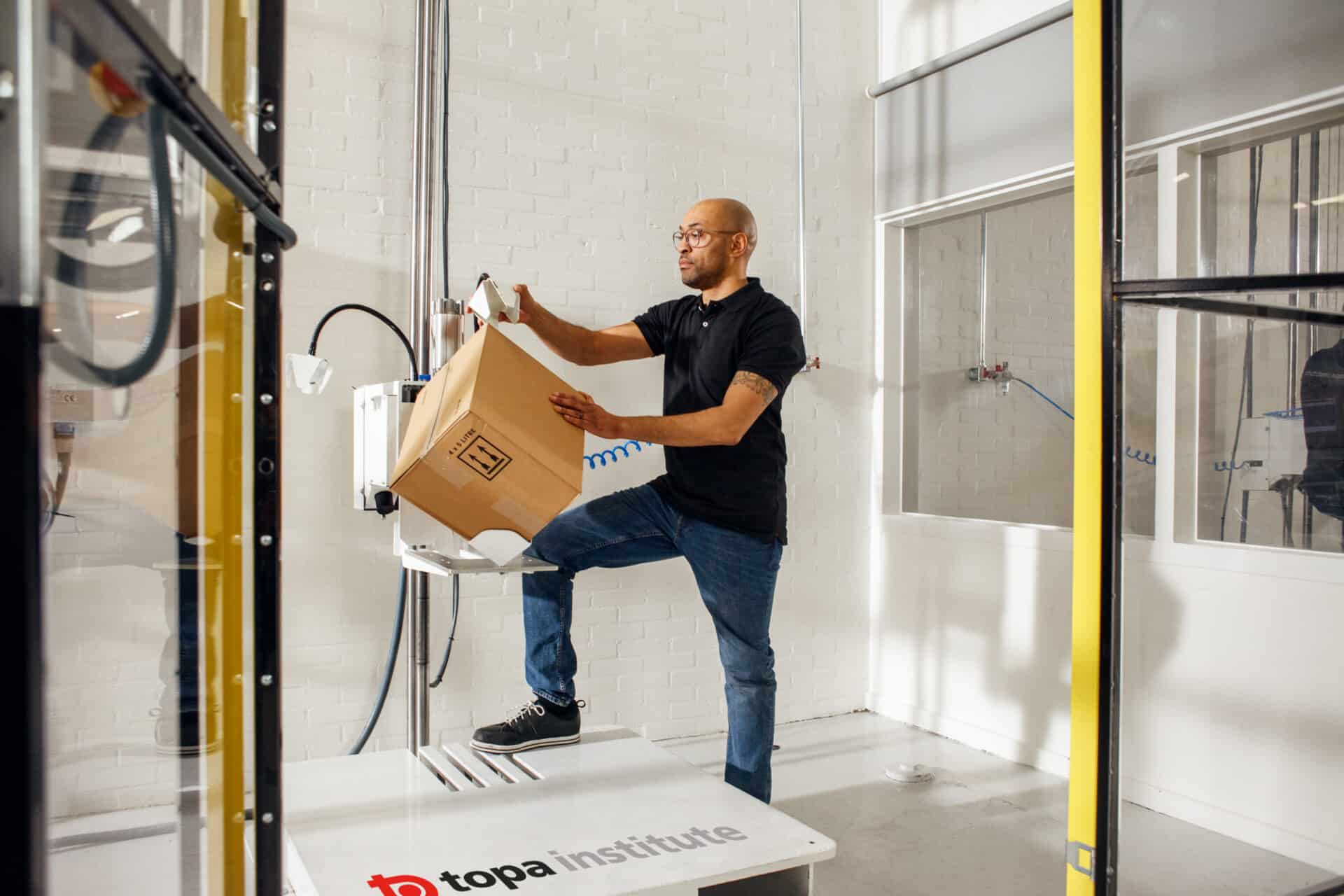

Realistic testing at the Topa Institute

Whatever path we choose, we want to be sure that the packaging performs as required. That’s why we have the Topa Institute: our in-house testing centre where we simulate realistic conditions. With various testing facilities, we replicate the transport journey, including vibrations, drops, and climate changes. This allows us to test whether the packaging can handle real-world challenges. Where needed, we test according to international standards such as ISTA 3A.

In practice: fewer returns

For Peblar, a manufacturer of charging solutions for electric vehicles, we developed packaging that was suitable for parcel shipping and met the appropriate testing standards. As a result, the number of returns dropped. With less damage occurring, fewer products had to be resent.

Go to the customer case from Peblar

Curious how you can reduce damage in your supply chain? We’d be happy to think along. Even a small change in your process or the right packaging solution can make a big difference.

Contact us via phone: +31 252 245 200 or email: info@topa.nl