Less space: optimise storage and transport

Space is valuable, in the warehouse, in trucks or on pallets. Every metre that isn’t used efficiently ultimately costs money. Packaging that doesn’t stack well, contains too much empty space, or simply isn’t suited to your processes results in unnecessary waste of storage and transport capacity.

That’s why at Topa, we don’t just look at protection, we also consider shape, size and stackability. ‘Less space’ is one of the seven focus areas we use to help organisations structurally reduce the Total Cost of Packaging (TCP). By designing packaging that’s more compact and better integrated into the logistics process, you can save space without compromising on functionality.

Where is space being wasted?

Excessive space usage in packaging happens more often than you might think. A box that’s slightly too large for the product often leads to shipping air and needing extra void fill. Packaging that doesn’t fit well on pallets or shelving means the available space isn’t being used to its full potential. And boxes without fixed sizing or a modular design can be awkward to stack and move.

By closely examining the dimensions, stacking behaviour and loading requirements of your packaging, you’ll often find plenty of opportunities for improvement, both literally and figuratively.

How to save space

We always begin with an analysis of the current situation: how are products currently stored and transported? Based on this, we determine which solution will be most effective. In some cases, a standard packaging option from our range already offers a clear benefit. In other situations, we develop a tailored solution that perfectly matches the product, the process, and the transport method.

We pay particular attention to factors like stackability, volume reduction and modularity. A package that fits standard pallet dimensions or can be logically combined with other items in a shipment directly contributes to space savings in storage and transport. With more units per square metre, warehouse and transport efficiency increases. In other words, you can do more with the same resources, or achieve the same with less.

In practice: more lamps, less space at Hortilux

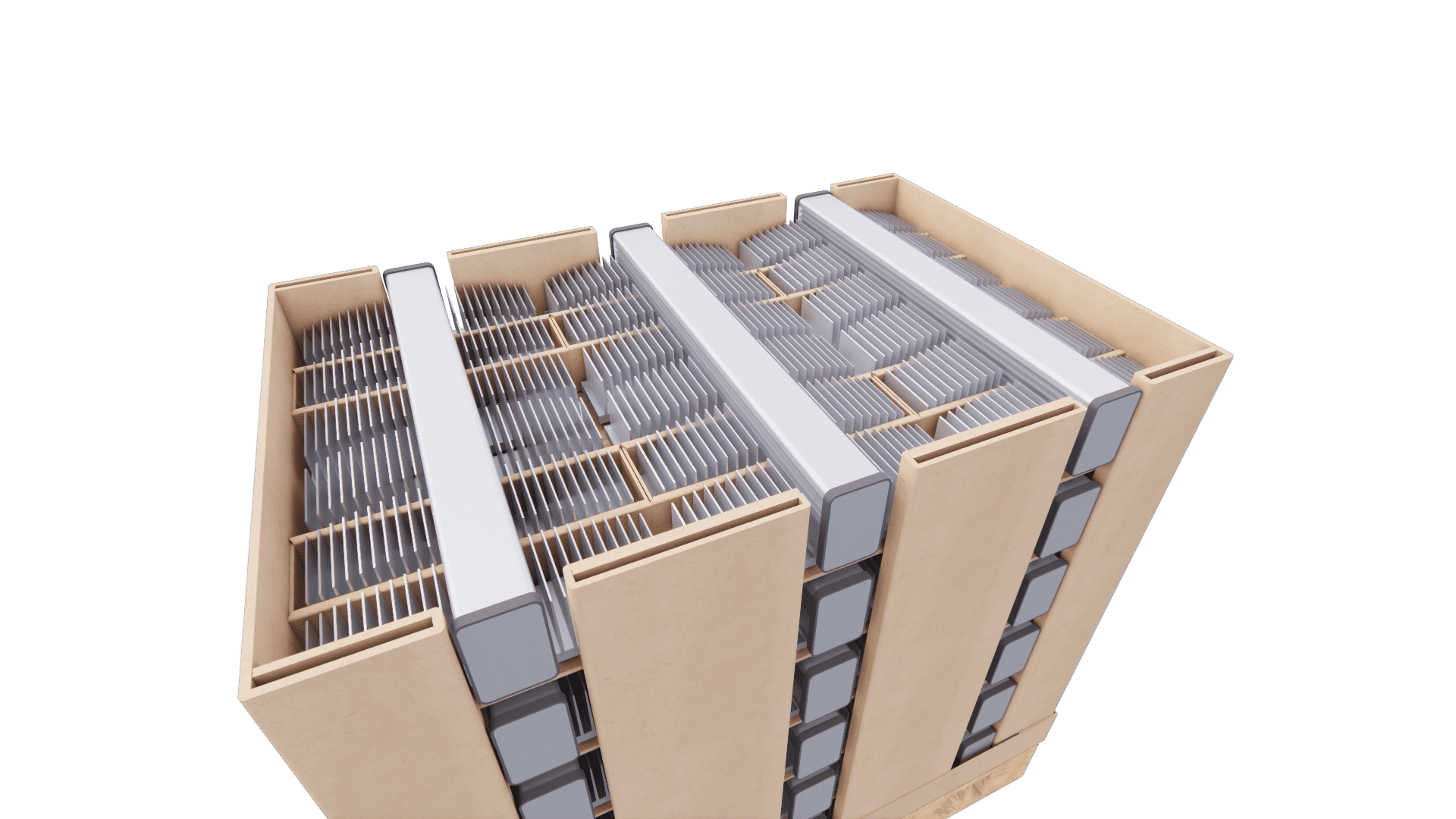

A good example is our collaboration with Hortilux, a manufacturer of horticultural grow lights. For their lamps, we developed packaging that not only protects the product but also makes clever use of available space. By housing multiple lamps in a single pack and designing the box for efficient stacking, the number of transport movements was significantly reduced.

At the same time, internal warehouse usage improved, as the new packaging took up far less floor space than the previous version. The result? Fewer pallets per shipment, lower storage costs, and a more efficient logistics process, all without compromising on protection.

Curious how you can get more out of your available space? We’d be happy to explore it with you. A well-designed package is not only strong, but also smart, and it can make all the difference both on the warehouse floor and during transit. Feel free to get in touch with us at +31 252 245 200 or info@topa.nl.