Which packaging material should I use?

Which packaging material is most suitable for the product to be sent is a question we get every day. However, this strongly depends on your wishes and requirements. Other factors also play a role, such as:

- What product would you like to ship

- What is the transport route of the product

- How many products you send per day/month

In addition, any wishes regarding sustainability and the environment may also come into play. We ask for as much information as possible about the product and its transport, so that we can offer the most targeted solution. To illustrate, we have protected and packaged a cool box in four different ways, and explain the advantages and disadvantages of each solution. One solution is not better than the other, but depending on the aforementioned factors, one solution may suit customer A better and another solution may suit customer B better.

Solution 1: Protect with air cushions

Air cushions are an ideal solution when you want to pack several products, each with its own shape and size. Depending on the product to be sent, you simply use more or less material around it. Besides that, it is a cheap way of protection. The disadvantage of air cushions is that the product needs to be packed in a proper way. If you wrap the air cushions nicely around the product, the product will be well protected. But when this is not done carefully, your product can be damaged. So it depends on the patience and precision of the packer.

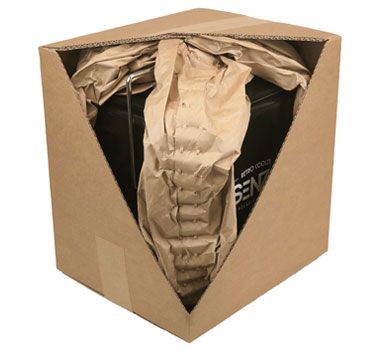

Solution 2: Protect with Padpak

Padpak is a green alternative to protection with air cushions, because you pack with paper. It also has similar advantages and disadvantages, but because it is paper and goes into a cardboard box, you only have one waste stream. And that is of course better for the environment. The disadvantage is that Padpak loses its cushioning effect the longer it is transported. This is because the crumpled paper becomes flatter and flatter as it absorbs any shocks during transport. If your product has to be transported over a long distance, this option is not an option, but for shorter distances this is a good and cheap way of protection.

Solution 3: Protect with foam buffers

Protection with custom-made foam buffers has several advantages. For example, foam retains its shape during the entire transport route. In addition, you cannot pack incorrectly with them, because the foam buffers fit in the box in one way. This makes it immediately clear whether the buffer is in the wrong place or not. And finally, the presentation of your product in foam is much more beautiful and well-kept. Because the foam buffers are custom-made for your specific product to be shipped, the disadvantage is that when the size of your product changes, you need a new custom-made foam buffer. And foam is a more expensive material than paper or air cushions.

Solution 4: Protect with cardboard buffers

A custom-made buffer can also be developed in cardboard. This gives you the same advantages of a foam buffer, without using plastic. However, in case of heavy impact during transport, cardboard can lose its protective function over time.