Working with the customer, we aimed for less when it came to sealing boxes

Less material loss, less time, less sick leave, lower costs

We worked with the customer to aim for less. The customer had been sealing boxes with PVC tape for years. Over recent years they had undergone substantial growth, meaning that many more packages were being sent out each day. So they started looking for a good alternative. In the end, the customer approached Topa to help them come up with a more sustainable, ergonomic and efficient way to seal their boxes. This resulted in less material loss, less time, less sick leave and lower costs.

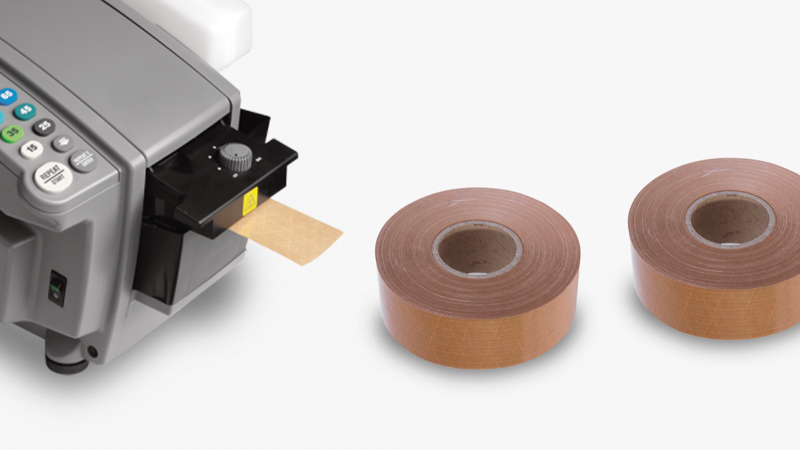

Our proposal to the customer was to carry out a number of tests using a tape machine in combination with reinforced and unreinforced tape.

An additional benefit of the tape machine is the fact that it is very ergonomic to use. This means less injuries and less sick leave. The person using it simply has to press the button for the right length. This way they do not put strain on their wrists or shoulders, as they would using a standard tape dispenser.

All the advantages:

- environmentally friendly alternative to tape: no material loss, resulting in less waste

- 20% less time spent on packaging: the machine makes the desired length automatically

- less injuries and sick leave: the machine is ergonomically designed

- lower costs: mechanical tape machines start at € 629.00.

The fully automatic tape machine shown here, model 555, costs € 1,743.00 - strong sealing material for less money

- resistant to temperature fluctuations

- seals permanently

The customer’s final result with paper tape in combination with a tape machine:

Quality: Paper tape adheres much better to the box. Reduced risk of damage and open boxes. Label adheres well to the tape. Reduced risk of ‘duds’, where the label has come off the box.

Consumption: Thanks to the better quality of the tape, the customer no longer needs to tape the boxes crosswise. This saves the customer costs: between 10 and 68% per year, depending on the choice of tape (unreinforced, reinforced, printed etc.)

Time: The packaging time has been reduced by 20% thanks to a more efficient way of working. And boxes are successfully sealed in one attempt. The paper tape does not come unstuck after the packaging process.

Sustainability: Working with paper tape means the box and tape do not need to be separated. This is the case with PVC tape. In addition to the saving in terms of consumption, paper tape in combination with the tape machine is a sustainable solution.

Ergonomics: The paper tape machine poses no increased risks in terms of ergonomics, since you do not need to make any difficult movements with your arm.

Employees’ thoughts: Employees are very enthusiastic about using the paper tape. Examples: “I don’t have to make any uncomfortable movements, really positive”, “Easy to learn”, “Tape adheres better to the box”.

Are you aiming for less too? Would you like to find out more about our mechanical tape machine from € 629.00 or about one of our fully automated tape machines from € 1,743.00?

Go to our webshop, send an email to info@topa.nl or phone 0252 245 245 and ask to speak to one of our packaging specialists.